Fittings

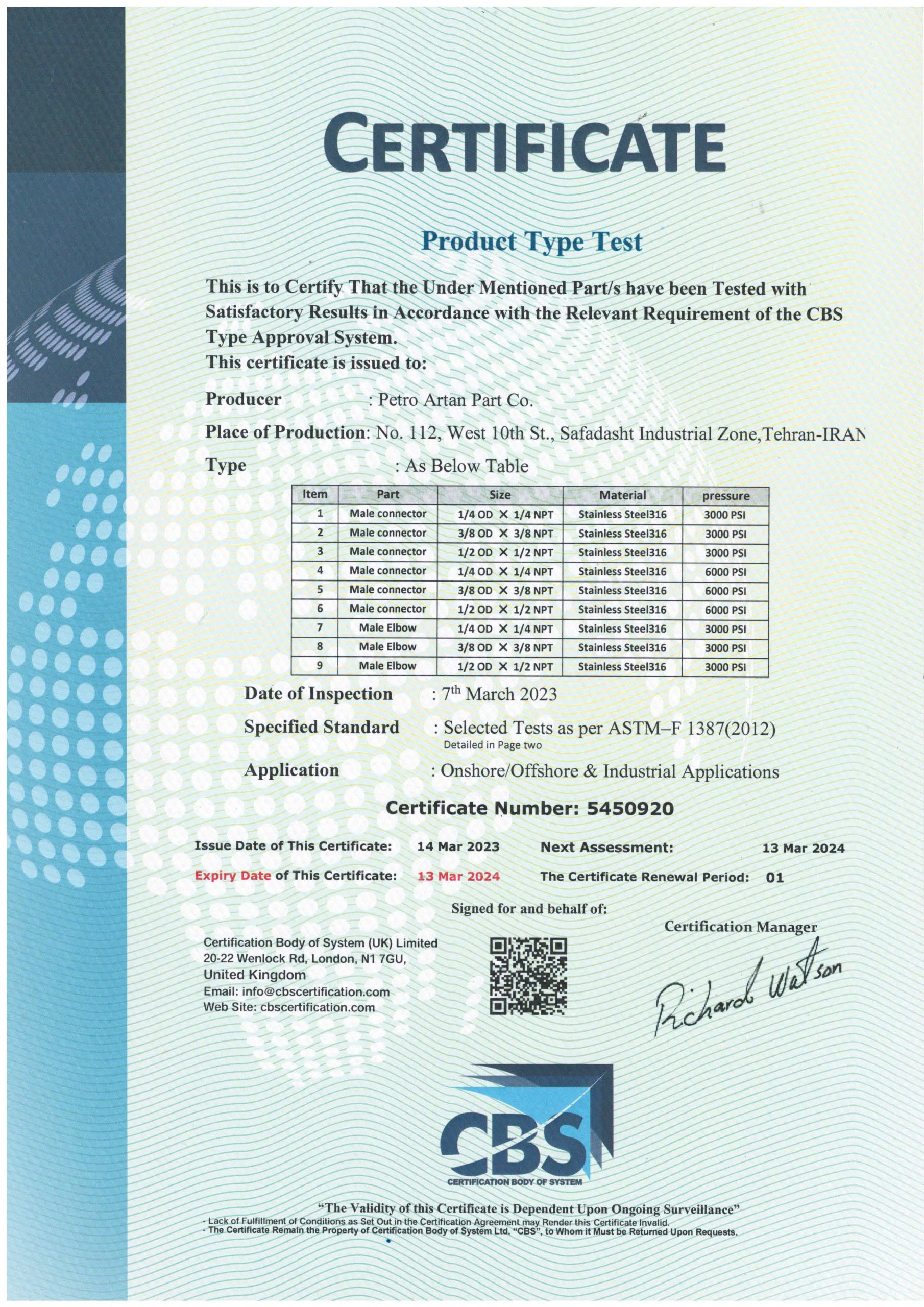

Pipe and tube fittings are being tested based on ASTM-F 1387(2012).

Type test are employed on random products and result containing below lines reported:

A. Sampling of the above mentioned items from production lines

B. Material verification review.

C. Witnessed of hydraulic proof pressure test.

D. Witnessed of hydraulic impulse vibration test in ambient temperature.

E. Witnessed of state gas pressure test.

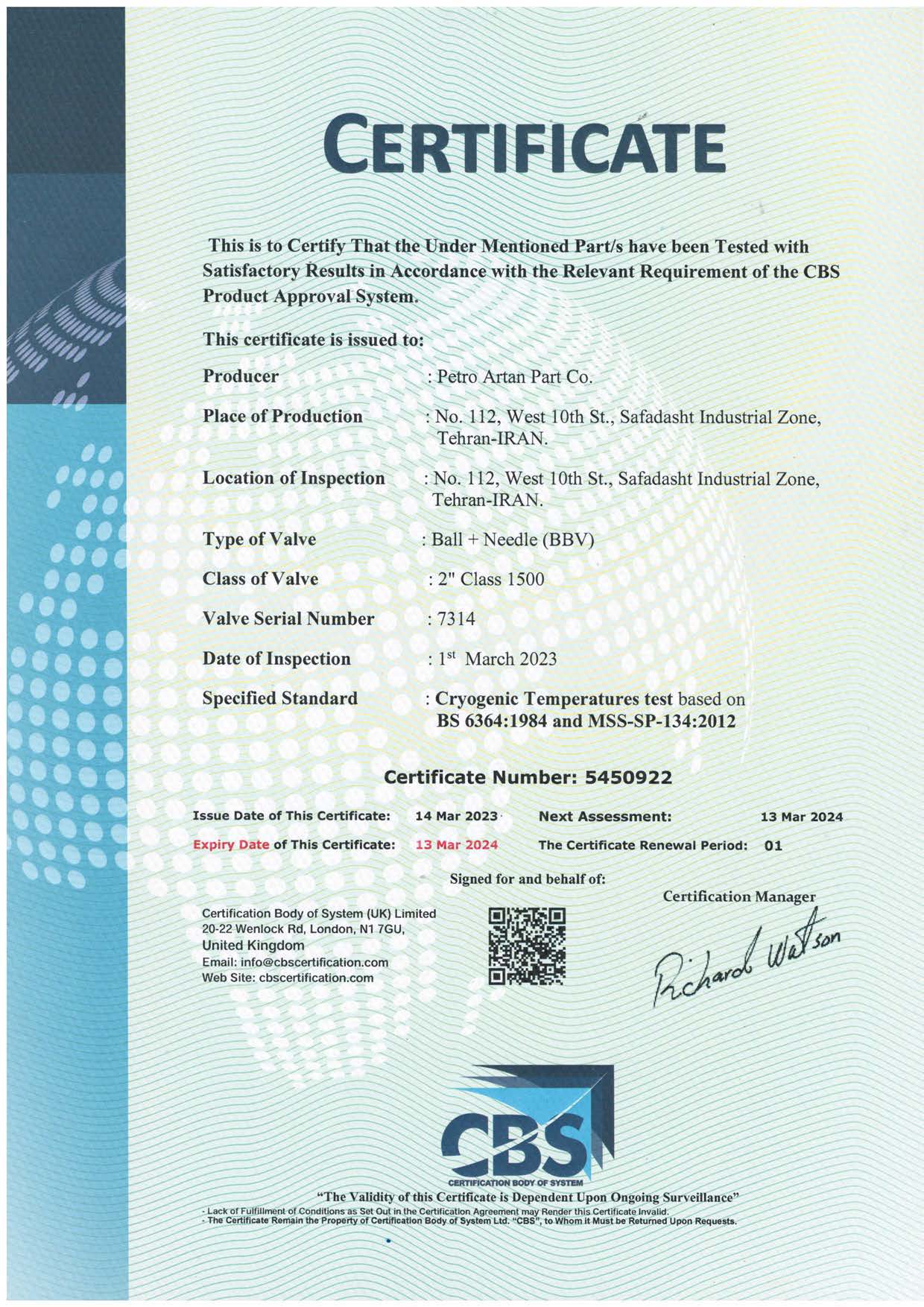

Fire Test

API 607 procedure dictates that a valve is enveloped in flames for 30 minutes while pressurized, after which it is force-cooled with water. Leakage of valve during the test should be checked. It simply means If there is a fire or explosion in any part of an industrial company, valve leakage should be lower than the standard threshold.

As part of PAP complete valve engineering package, we operate a state of the art fire testing facility. The actual testing is controlled and monitored in a separate control room that is equipped with custom fire test control software, sensors and monitored with recording capabilities.

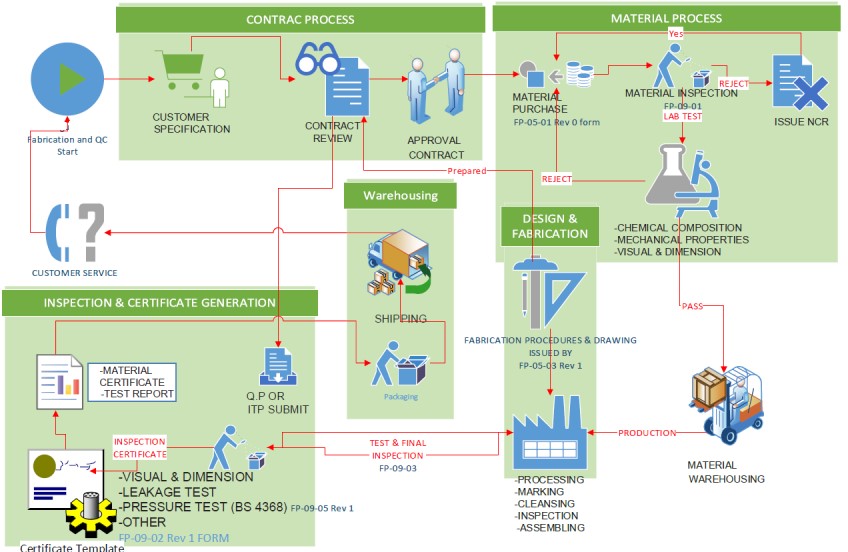

Iso & Tracing System

PAP strictly traces products from production to the final packaging. Identify, track and trace elements of a product as it moves along the supply chain from raw goods to finished products. This provides numerous benefits such as investigate and troubleshoot issues or reject the product.